TopApparelcn uses the original imported American DuPont ™ Kevlar yarn to produce knitted fabrics with excellent quality and excellent performance, which has been well received by customers in the fields of military and police protection, security protection and aerospace.

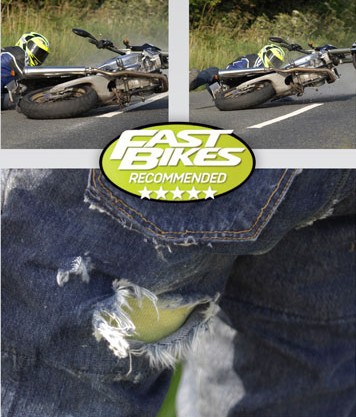

DuPont ™ Kevlar knitted fabric is a material widely used in the field of labor protection all over the world, and has been recognized by customers at home and abroad for its superior heat resistance, abrasion resistance, cut resistance and impact resistance.

Chemical name | Para-aramid yarn knitted fabric |

Fiber brand name | DuPont ™ Kevlar ® |

Fiber Origin | United States |

The place where the finished fabric is produced | China. Dongguan |

Material type | K29 |

color | Natural color (yellow), can be customized any color |

grain | Rib |

WIDTH(MM) | 1000、1500、2000 |

Gram weight(g/㎡) | 180, 220, 280gsm (any gram weight can be customized according to customer requirements) |

THICKNESS (MM) | 0.3-0.8 |

Packing (rice/roll/carton) | 50、100 |

Excellent thermal properties

Excellent thermal properties

Decomposition temperature | Kevlar knitted fabric does not melt; At a heating rate of 10°C/min, the decomposition temperature in air is 427°C-482°C, while in nitrogen it is about 538°C. The decomposition temperature varies with different heating rates and exposure times. |

Effect of high temperature on expansion and contraction | Increasing the temperature will reduce the modulus, tensile strength and elongation at break of Kevlar knitted fabrics. This factor should be taken into account for long-term use at temperatures ranging from 149°C to 177°C or higher. |

Effect of high temperature on scale stability | When exposed to hot or hot water, Kevlar knitted fabrics do not shrink like other organic fibers. Most other fibers undergo irreversible shrinkage. The coefficient of thermal expansion in the axial direction of Kevlar knitted fabrics is very small and negative. |

Effect of low temperature (ultra-cold) conditions | When exposed to minus 46°C, the tensile properties of Kevlar knitted fabrics are not negatively affected, and there is no embrittlement or degradation at temperatures of minus 196°C. |

Excellent mechanical properties

Kevlar knitted fabric is a new type of composite material, which has ultra-high strength (>25g/D), which is 6 times that of high-quality steel of the same density, 4 times that of nylon, 3 times the amount of high-quality steel and E glass fiber, 2 times the toughness of steel, and only 1/5 of steel.

flammability

Kevlar knitted fabric is inherently flame retardant, but it is capable of ignition (oxygen index of 29). When the ignition is removed, the combustion usually stops, but if the pulp or dust is ignited, it can continue to smolder. In experiments, it has been shown that Kevlar will not continue to burn when the Kevlar knitted fabric is removed after 12 seconds of contact with the fire source. As the fabric thickness increases, the afterglow time is extended, but the burn length does not increase. It does not produce any “drippings”, which allow the flame to spread, which is a common problem with other organic fibers.

The effects of ultraviolet light

Like other polymer materials, Kevlar knitted fabrics are sensitive to ultraviolet light. Unprotected for a long period of time can fade from color to brown, and long-term exposure to UV light can cause loss of organic properties, depending on wavelength, exposure time, and radiance.

Kevlar knitted fabric is self-shielding, acting as a protective barrier to the outer fiber properties and protecting the inner fibers of the fiber or fabric. The influence of ultraviolet light on Kevlar knitted fabrics can be effectively protected by means of an outer layer or coating.

garment series

fabric in stock

Xin Li

Xin Li